Partial Fillet Weld Perpendicular Loading Applied Stress

The Partial Fillet Weld Perpendicular Loading Applied Stress Calculator finds the stress created from a tee section load partial penetration weld perpendicular loading applied stress.

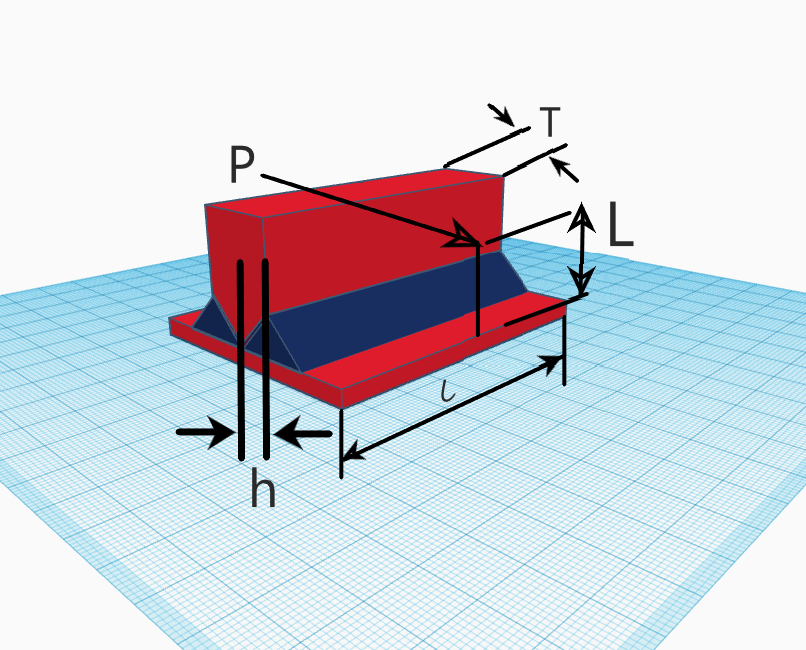

INSTRUCTIONS: Choose units and enter the following:

- (T) Plate Thickness

- (P) Total Applied Force

- (L) Height of Lever Arm

- (h) Weld Thickness

- (l) Length of Weld

Stress (σ) and Shear Stress (τ): The calculator returns the answer in psi. However this can be automatically converted to compatible units via the pull-down menu.

The Math / Science

There are five basic types of welded joints: butt, lap, tee, corner and, edge joints.

Butt joints are formed when two plates are butted together. The connection is normally made with a full or partial penetration weld.

Lap joints are made when two members with flat surfaces overlap each other. The connection is normally made with fillet welds on the edges of the connected parts.

Tee joints have one plate element that "T"'s into another. The joint can be made with fillet, partial penetration, or full penetration welds.

Corner joints are a type of tee joint. They occur at the edges of two plates.

Edge joints join the edges of two plates laid together. The connection is made with partial penetration welds.

To find the amount of stress, use the formula:

σ = (3TPL) / lh(3T2 - 6Th + 4h2)

where:

- σ = stress in the weld

- T = thickness of the plate

- P = total applied force

- L = height of lever arm

- l = length of the weld

- h = thickness of the weld

To find the amount of shear stress, use the formula:

τ = P / (2 ⋅ l ⋅ h)

where:

- τ = shear stress

- P = total applied force

- l = length of the weld

- h = thickness of the plate

Welding Calculators and Constants

- Bend Allowance Calculator

- Weight of Aluminum Square Bars

- Steel Wire Deposition Rate Calculator

- Welding Heat Input Calculator

- Groove Weld Potential Root Cracking Calculator

- Weight of Hot Rolled Steel Flats

- Modulus of Elasticity for Martensitic Stainless Steel

- Brinell Hardness of Gray Cast Iron

References

StructX (https://structx.com/welded_connections.html)

A Beginner's Guide to the Steel Construction Manual, 13th ed. (https://www.bgstructuralengineering.com/BGSCM13/Contents.htm)

- Comments

- Attachments

- Stats

No comments |