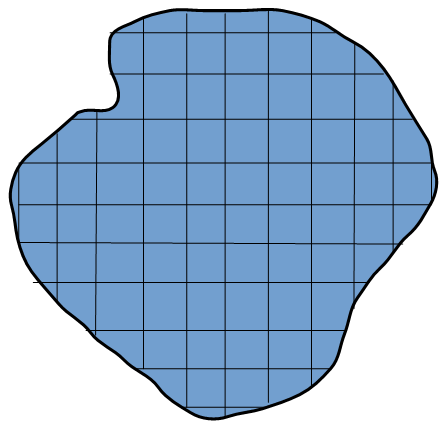

The Rebar in Irregular Shaped Slab calculator estimates the total length and weight  of reinforcement bars (rebar) needed for an irregular shaped concrete slab. NOTE: this calculator was updated on 16 Feb 2022 to accommodate the inset of rebar placement from the edge of the slab. The net result is a more accurate and less conservative estimate.

of reinforcement bars (rebar) needed for an irregular shaped concrete slab. NOTE: this calculator was updated on 16 Feb 2022 to accommodate the inset of rebar placement from the edge of the slab. The net result is a more accurate and less conservative estimate.

INSTRUCTIONS: Choose units and enter the following:

- (A) Approximate Area of the irregular shaped slab (e.g. 72 ft2)

- (rP) Estimate of Perimeter of the slab (e.g. 178 ft)

- (i) Inset of Rebar from Edge of Slab

- (D) Depth of Slab

- (S) Size of Rebar. Choose from the pull-down list size 2 to size 20.

- (oC) On-center spacing of the rebar.

- (M) Number of Rebar Mats

Irregular Slab Rebar and Concrete (IR): The calculator returns:

- approximate length of rebar in slab in feet.

- approximate weight of rebar in pounds, and the

- approximate volume of concrete in cubic yards.

However, these can be automatically converted to compatible units via the pull-down menu.

The Math / Science

The rebar weight algorithm calculates the length and weight of reinforcement steel bars in an irregular shaped concrete slab. The algorithm uses the Rough Area, Perimeter and the onCenter spacing to estimate the total length of rebar in one mat. The total length of rebar is the length in one mat times the number of mats.

Once the algorithm calculates the length of rebar, the length is used with the user specified rebar size, and density constants from the vCalc library to calculate the total weight of the reinforcement steel bars. The area and depth are used to compute the volume of concrete. The formula the length of rebar in one mat of an irregular shaped slab is:

L = 4*oC*(A/(2*oC*oC)) + rP/2

where:

- L = length of rebar in an irregular slab

- oC = on center spacing of rebar

- A = area of slab

- rP = perimeter of slab

To accommodate an inset from the edge of the slab for the placemen to the rebar, the area (A) and perimeter (rP) have to be reduced BEFORE the formula above. The method used is to treat the slab as a circular slab and reduce the area and perimeter accordingly as follows:

- //Reduce area by inset

- rR = sqrt(A/PI) - i

- A = PI*rR*rR

- //Reduce perimeter by inset

- rR = rP/(2*PI) - i

- rP = 2*PI*rR

The calculation determines the need for an extra rebar using an internal tolerance for for a spacing fraction that exceeds the tolerance with a default of 1". It also assumes that the uncut rebar is in 40' lengths and that lapping is needed for dimensions in excess of 40`. Furthermore, the lapping factor, when lapping is needed, is 40. For the same calculations with the ability to add a different "uncut" length and/or a different lapping factor CLICK HERE.

Reducing Rebar Waste

A major challenge with rebar in an irregular slab is minimizing wasted rebar. The general guidance is this. When possible, start with the longest cross-section of of your slab and work outwards from there. These will be the longest stretches of rebar in your slab. When you cut off the ends, line them up in a row from shortest to longest. When you get to shorter runs, first see if there is a cut-off section of rebar from your row of cut-offs. This is only a little extra work and will save in both materials and labor removing cut-offs at the end of the project.

General Rebar Information

Rebar is short for reinforcing bar. Rebar is a roughly circular steel bar with ribs used to provide added tensile strength to concrete structures. Rebar is put in place before concrete is poured. When the concrete has hardened, the concrete around the rebar ribs keep the rebar in place. Rebar and concrete expand similarly with temperature variations. This all has the net result of substantially added tensile strength when rebar is part of the concrete form. Carbon steel is the most commonly used material for rebar, which may also be coated with zinc or epoxy resin.

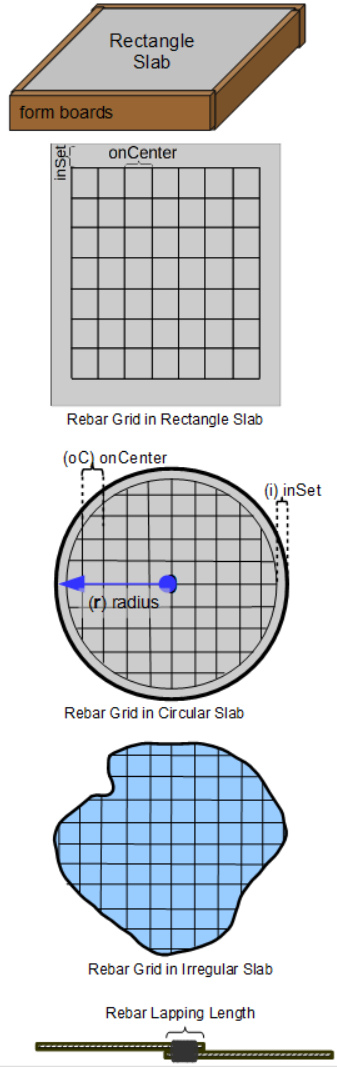

Rebar is laid out in grids, crisscrossed patterns of rebar, tied at the intersections where runs of rebar touch. The grids have spacing between the rebar rows, and they are placed within the concrete form by a specified inset from the edge of the concrete. Multiple parallel grids, at uniform space intervals, are referred to as rebar mats.

Rebar Terms

- Rebar - reinforcing steel bar.

- Stick - one length of rebar. In the U.S., the most common lengths of rebar sticks are 20', 40' and 60'.

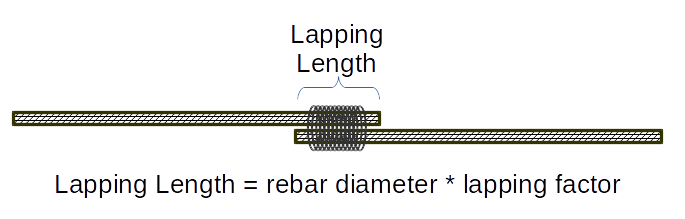

- Lapping - when two sticks of rebar are overlapped and bound together.

- Lapping Factor - the multiple of a rebar diameter used to specify appropriate rebar lapping length.

- Mat - a crisscross grid of rebar sticks. There may be more than one mat with space in between mats.

- Size - the indicator of the diameter of rebar sticks. Note: guage is not a correct term for rebar.

Rebar Size

In the United States, rebar sizes are in increments of 1/8th inches in diameter. Therefore, size 4 is 4/8th of an inch, which is 1/2", and size 8 is a full inch in diameter. Based on this and the density of steel used in rebar, the Rebar Size Table contains reasonably accurate specifications of rebar linear weight and lateral (face) area based on rebar size.

Rebar Lapping

The most common lengths of pre-cut rebar in the United States are 20`, 40' and 60'. These are known as rebar sticks. When the dimensions of a slab, wall or other form exceed the length of a single stick of rebar, it is required to overlap and tie rebar pieces to create the added length. This process is called lapping, and the length of the overlapping rebar is the rebar lapping length. The length of the lap is specified by a "Lapping Factor (LF)" which is often 40 or 60 times the diameter of the rebar. So, a Lapping Factor of 40 for size 4, would dictate a lapping length of 20 inches (40 x 4/8") .

Engineering specifications of a lapping factor should always be applied.

Rebar Tools

A class of rebar tools, both powered and manual, have been developed to aid construction workers in working with rebar. These include the following:

- Rebar Cutters are used to cleanly and safely cut sections of rebar.

- Rebar Benders are used to bend rebar sticks precisely to fit into concrete forms.

- Rebar Tiers are used to tie rebar grid intersections and for rebar lapping.

Reinforcement Bar (rebar) Functions

- Length of Rebar in Grid: Computes the total length of rebar needed for one or more mats of rebar in a concrete slab based on slab dimensions, rebar spacing, inset from slab edge, number of mats, length of pre-cut rebar sticks, and a rebar lapping factor.

- Weight of Rebar in Grid: Computes the total length and associated weight of rebar needed for one or more mats of rebar in a concrete slab based on slab dimensions, rebar spacing, inset from slab edge, number of mats, length of pre-cut rebar sticks, a rebar lapping factor and the size of rebar.

- Rebar and Concrete in Slab: Computes the total length and weight of rebar and the volume of concrete needed for a slab. The weight and volume calculations take into account the concrete displaced by the rebar. Also provides the total weight of the slab and the cost of rebar.

- Wall (Rebar Concrete and Forms): Computes the length and weight of reinforcement bars (rebar), volume of concrete and the surface area of forms for a wall based on the dimensions of the wall.

- Rebar in an Irregular Shaped Slab: Estimates the total length and weight of reinforcement bars (rebar) needed for an irregular shaped concrete slab.

- NEW Rebar Around Irregular Shaped Area: Estimates the total length and weight of rebar and concrete needed for a slab with an irregular shaped void (e.g. swimming pool) inside the slab.

- Rebar in a Circular Slab: Estimates the total length and weight of reinforcement bars (rebar) needed for a circular shaped concrete slab.

- Rebar Lapping Length: Computes the length overlap needed at rebar joints based on rebar size and a lapping factor.

- Rebar Cost Estimate: Computes the total cost of rebar based on the length being purchased, length of the individual pieces being bought and unit price of one piece of rebar.

- Weight of Rebar: Computes the total weight of rebar based on the length and size of rebar.

- Concrete Displaced by Rebar: Estimates the net weight added to a slab by adding rebar, and the reduction in concrete cause by adding rebar.

- Weight of Slab with Rebar: Estimates the weight of a rectangular slab with rebar base on the slab dimensions, rebar size and space and the know density of both concrete and rebar (steel). It also includes the individual weight of the components and the volume of concrete accounting for that displaced by rebar.

- Rebar Price per Pound: Computes the price per pound of rebar based on the unit cost of a rebar stick, its length and size (2-20).

- NEW Chairs for Rebar Grid: Computes the number of chairs needed to suspend a rebar grid.

- NEW Rebar and Concrete in Slab by Area: Estimates the total length and weight of rebar and the volume and weight of concrete needed for a slab by the surface area, depth and rebar specs (size, spacing, inset, mats, etc.).

See also the Calculadora de Barras de Refuerzo Collection for the Spanish version of the above.