Groove Weld Potential Root Cracking Calculator

The Groove Weld Potential Root Cracking Calculator finds the whether or not the groove weld has a potential for root cracking based on the width-to-depth ratio (1.0-1.4).

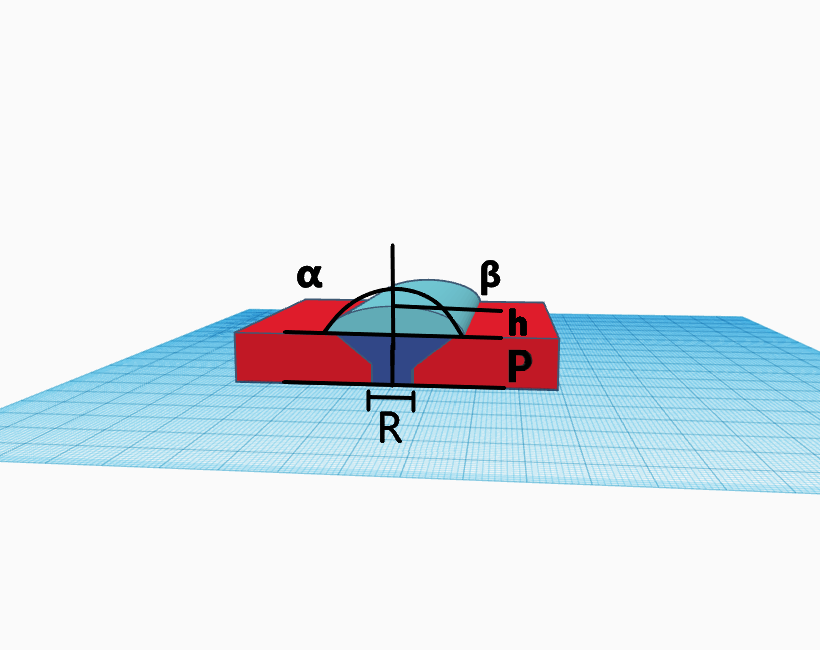

INSTRUCTIONS: Choose units and enter the following:

- (R) Root Opening

- (α) Bevel Angle No. 1

- (β) Bevel Angle No. 2

- (P) Penetration Depth

- (h) Bead Height

Groove Weld Potential Root Cracking Ratio: The calculator returns the answer as a decimal.

The Math / Science

The recommended width-to-depth ratio for any combination of V-groove or beveled groove welds ranges from 1.0 to 1.4. Any decimal within this range typically prevents groove weld root cracking. It is important to note that proper root geometry does not ensure complete fusion of the metals or the absence of slag inclusions.

To find the groove weld root cracking potential ratio, use the formula:

Wd=R+h(tanα+tanβ)h+P

where:

- W/d = bead width to bead depth ratio

- R = root opening

- α = bevel angle no. 1

- β = bevel angle no. 2

- P = penetration depth

- h = bead height

Example: A double V-groove weld detail has an included angle of 32 degrees and a root face dimension of 1/4 inch. To complete the design, a complete joint penetration (CJP) groove weld is to be made without backgouging. Will this result in a preferred width-to-depth ratio? Is there a potential for root cracking? Assume a penetration depth of 3/16 inch, a bead height of 1/2 inch, and a zero inch root opening.

Preferred width-to-depth ratio: W/d = 1.0-1.4

W/d = (R + h (tanα + tanβ)) / (h + P)

W/d = (0" + 0.5" (tan16° + tan16°)) / (0.5" + 0.1875")

Fractions have been changed to decimals and the included angle of 32° has been halved for the two separate bevel angles.

W/d = 0.2867 / 0.6875

W/d = 0.4171

This ratio (0.4171) is much less than the preferred ratio of 1.0-1.4, thus raising the potential of centerline cracking.

Welding Calculators:

- Bend Allowance Calculator: Computes Bend Allowance based on the thickness of the material, bend angle, inside radius, and K factor.

- Weight of Aluminum Square Bars: Computes the average weight of aluminum bars based on the number and dimensions of the bar, and an average density of 2700 kg/m3 for aluminum bars.

- Aluminum Wire Deposition Rate Calculator: Estimates the rate at which a welding wire is converted into weld metal using the electrode diameter, wire feed speed, and electrode efficiency.

- Welding Heat Input Calculator: Estimates the amount of heat or thermal energy that is introduced to a material when a weld is made using the arc voltage, current, and travel speed.

- Groove Weld Potential Root Cracking Calculator: Determines whether or not the groove weld has a potential for root cracking based on the width-to-depth ratio (1.0-1.4).

- Weight of Hot Rolled Steel Flats: Computes the average weight of steel flats based on the number and dimensions of the flats, and an average density of 7800 kg/m3 for steel flats.

- Modulus of Elasticity for Martensitic Stainless Steel: The measure of stainless steel's tendency to deform elastically when a force is applied.

- Brinell Hardness of Gray Cast Iron: Measure of gray cast iron's ability to resist permanent indentation deformation.

- Weight of Brass Rounds: Computes the weight of any number of brass round bars based on the number of rods, their dimensions, and an average density of 8,600 kg/m3 for brass.

References

Tools for Reviewing Welding Procedures (https://app.aws.org/mwf/attachments/11/253611/TOOLSFORREVIEWINGWELDINGPROCEDURES.pdf)

Collections

- Comments

- Attachments

- Stats

No comments |